SHUKUMA FLOORING PRODUCTS

Everyone at Shukuma Flooring is committed to provide prestressed hollow core concrete flooring products and installation services to our clients, which meet and often exceed their requirements.

We regard our clients as our most important stakeholders in our business and we remain dedicated to meet their needs and expectations at all times. This is done in a professional, cost effective and safe manner. We will always strive to improve the way in which this is accomplished.

The underlying quality system has been established in accordance with ISO9001:2015 International Standard and this Policy serves as a framework for setting and reviewing the Company’s objectives.

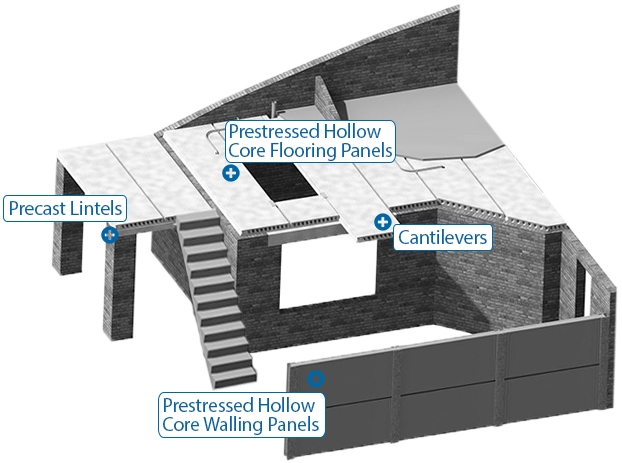

PRESTRESSED HOLLOW CORE CONCRETE FLOORING PRODUCTS

The SHUKUMA approach to installing floors, roofs and many other applications where pre-stressed slabs are suitable, offers more advantages than the traditional product. Among other benefits, contractors now enjoy increased efficiency without the need for storage space and props on often crowded sites.

Already a success in other parts of the country, the notion of concrete sections, designed in-house for specific purposes, makes a lot of sense.

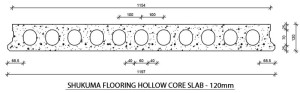

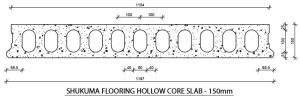

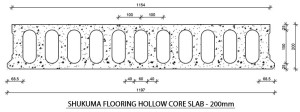

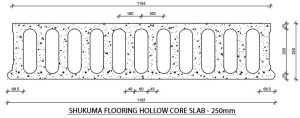

HOLLOW CORE SLABS – 120MM / 150MM / 200MM / 250MM

Cores are typically either circular or elliptical. Slabs may be reinforced or prestressed and are designed as ribbed slabs.

The hollow cores afford a reduction in self-weight of 30% or more, compared with a solid slab of the same depth. For most applications, no propping is necessary during construction, but crane access is essential.

An erection rate of up to 600 m² per day is possible.

Alternative methods of casting slabs are:

- Cast in conventional moulds with coreformers cast-in or removed.

- Cast on a long prestressing line being extrusion slipform methods.

The cast-in-mould method is used for reinforced concrete and longitudinal cantilever reinforcement may be incorporated if required.

The extrusion or slipform methods are suitable for a pretensioned prestressed long-line system of manufacture, without transverse or shear steel.

Manufacturing beds are typically 100 – 150 m long and the slab is sawn to required lengths before lifting. The longitudinal edges of the precast units are designed and profiled to receive grout in the joints and create a shear interlock which provides load transfer and prevents differential deflection.

The top surface is generally prepared to receive a screed or structural topping. Because they are cast against a steel surface, the soffits are smooth and ready to receive a decorating finish direct without the need for plastering.

Reinforced hollow core slabs are designed as simply supported ribbed slabs in the conventional manner. However they are more versatile than the prestressed slab, since longitudinal top reinforcement can be cast-in for cantilever action.

Prestressed hollow core slabs are designed as simply supported pretensioned ribbed slabs, in accordance with the requirements of SABS 0100-l or the appropriate National Code. The prestressing force opposes the tendency to downward deflection and causes an upward camber in the units under no-load conditions.

Hence, together with the high-strength concrete employed, larger span/depth ratios can be achieved than with reinforced concrete.

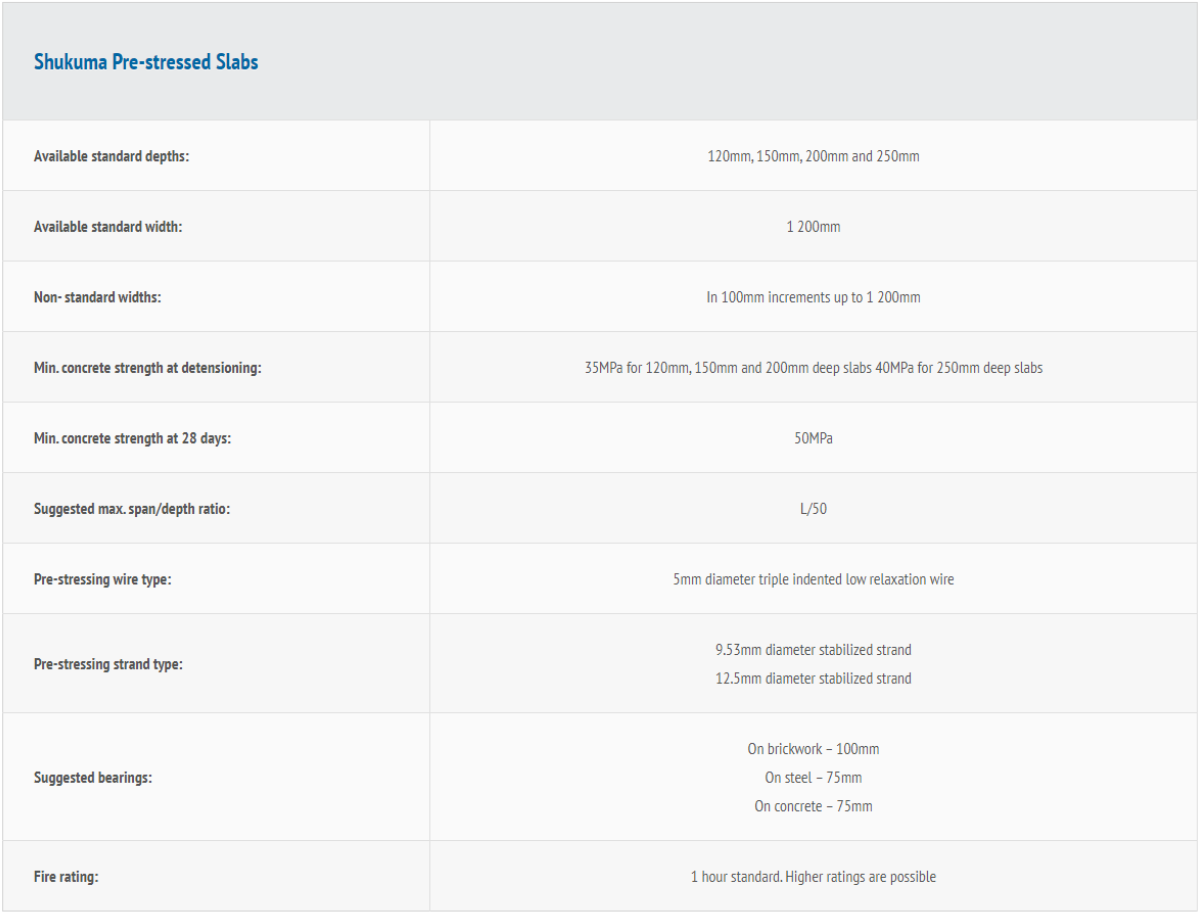

Structural Details

| Shukuma Pre-stressed Slabs | |||

|---|---|---|---|

|

Available standard depths: |

120mm, 150mm, 200mm and 250mm |

||

|

Available standard width: |

200mm |

||

|

Non- standard widths: |

In 100mm increments up to 1 200mm |

||

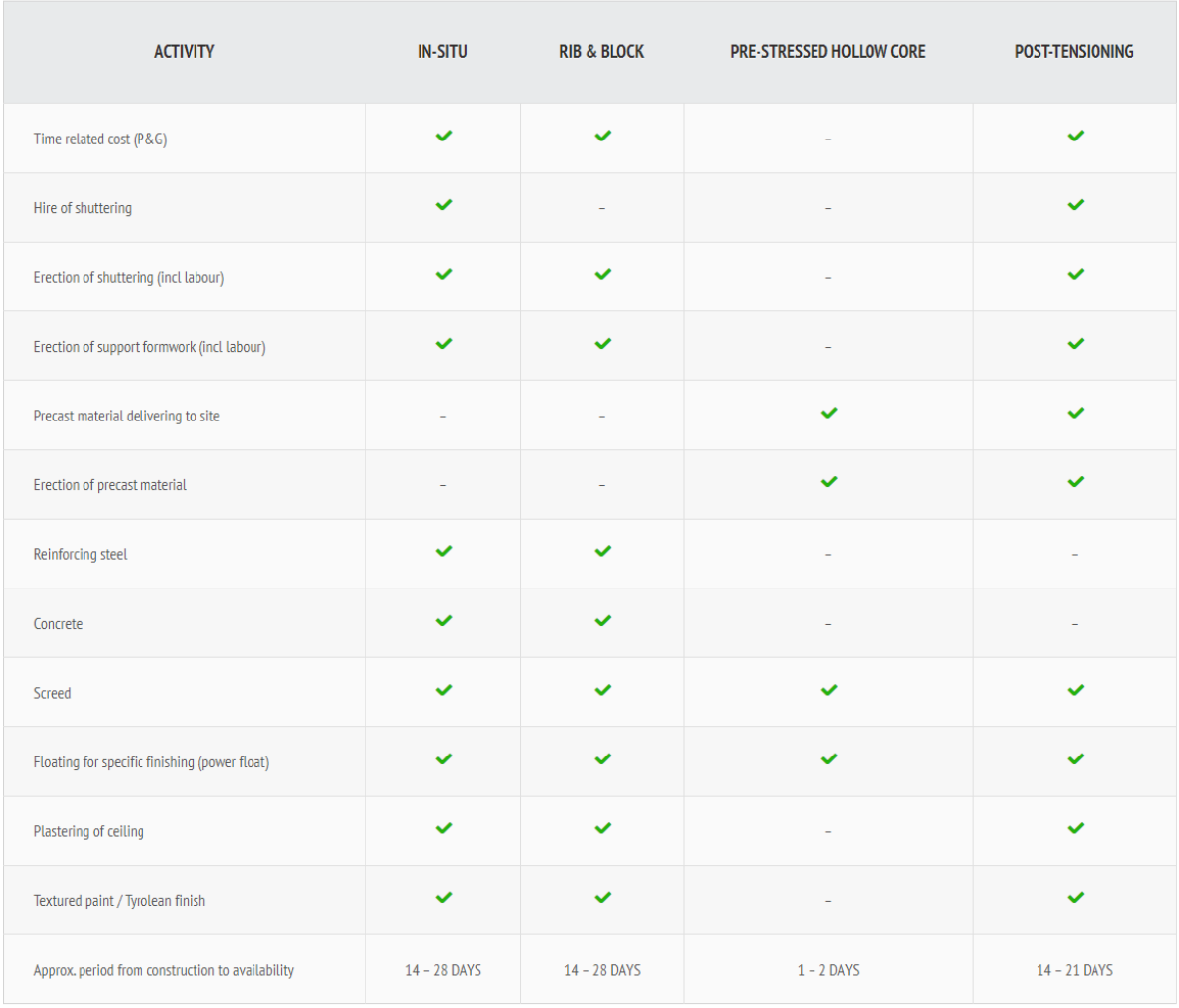

PRICE COMPARISON FOR DIFFERENT FLOORING SYSTEMS

| Shukuma Pre-stressed Slabs | |||

|---|---|---|---|

|

Available standard depths: |

120mm, 150mm, 200mm and 250mm |

||

|

Available standard width: |

200mm |

||

|

Non- standard widths: |

In 100mm increments up to 1 200mm |

||